INTRODUCTION

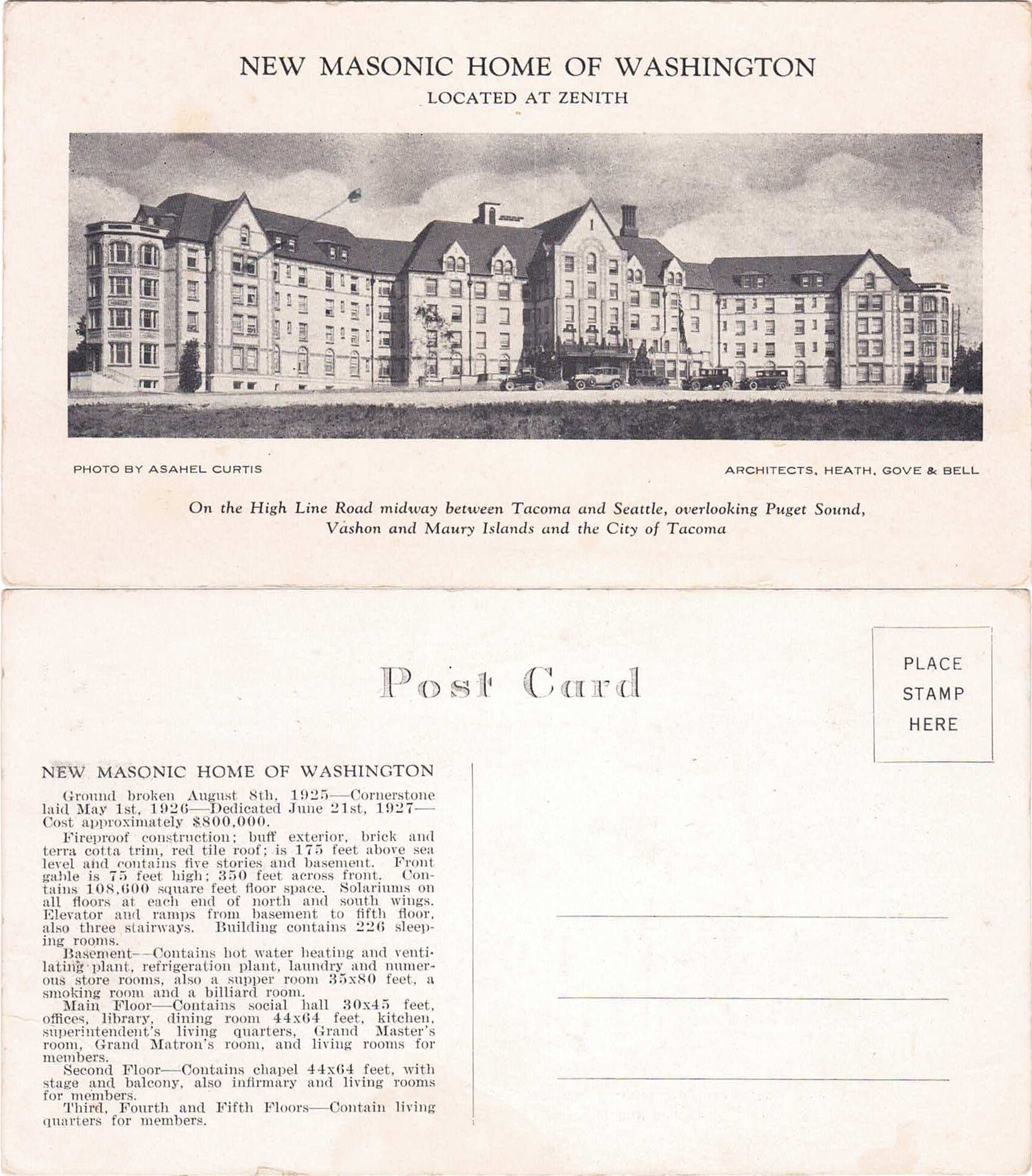

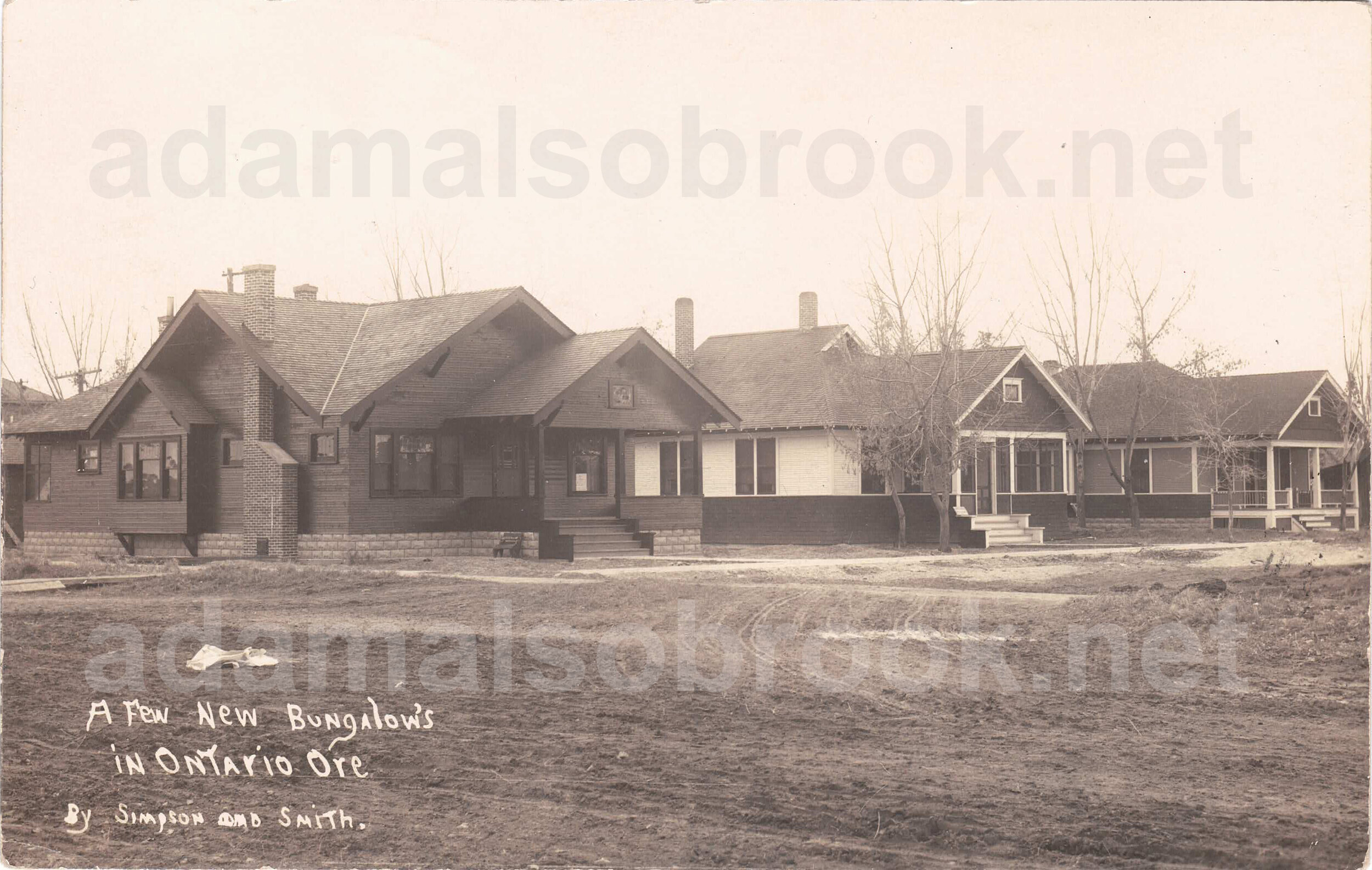

This real photograph postcard (RPPC) was mailed from Toledo, Oregon to London, England on July 17, 1924. The front of the card is inscribed “Residences, Toledo, Ore.,” but the exact location of these four houses and garage was not indicated either on the postcard or in the barely intelligible inscription on the back.

However, for readers familiar with some of my recent research and writing projects on this website, this was a minor setback to my learning exactly where these buildings were located. I narrowed down the span of years during which these buildings were most likely constructed using a combination of historic aerial photographs, fire insurance maps, and Google Maps. The wood plank road and brushy vegetation in front of the houses was another clue I was able to use to pinpoint their location in Toledo.

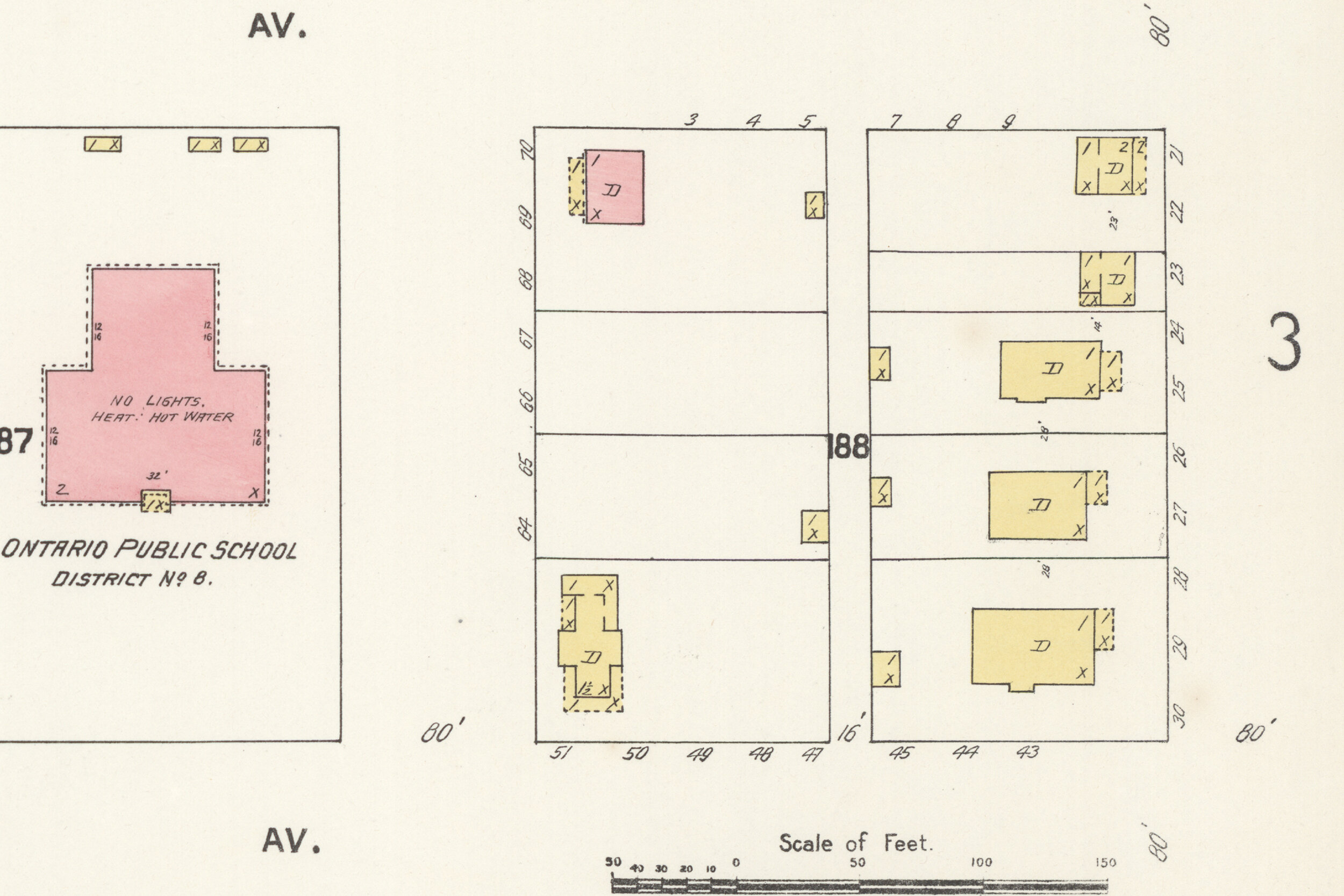

A little bit of sleuthing revealed that these buildings were located at the southeast corner of SE 7th Street and SE Fir Street in Toledo, which is a city in central Lincoln County, Oregon (Sanborn 1925:5). It appears that the garage and the four houses still exist where they were constructed about 100 years ago (Google 2021). With the location of the buildings identified, I then set about to learn what I could about this part of Toledo and some of the historical figures involved in their development and construction.

THE FOUNDING OF TOLEDO, OREGON

On December 21, 1865, President of the United States Andrew Johnson signed an Executive Order which allowed European American settlers in Oregon to take reservation lands that had been set aside for the native Siletz peoples. A native of Ireland, John Graham and his family emigrated to Oregon from Toledo, Ohio and were among the first European American settlers to claim some of the land that had been forcibly taken from the Siletz in what is now Lincoln County. In 1866, John Graham established Graham’s Landing on the banks of the Yaquina River about fourteen river miles east of Newport. A post office was established in 1868 and named by John Graham’s son Joseph after their previous place of residence in Ohio (Confederated Tribes of Siletz Indians 2021; City of Toledo 2021; Wikipedia 2021).

Less than twenty years later in the spring of 1884, the tracks of the Willamette Valley & Coast Railroad Company reached Toledo from Yaquina, which was located on the Yaquina River about 3 miles southeast of Newport. By December 1884, the same company’s tracks extended eastward another 62 miles to Corvallis, and by early 1887 the line had reached another 12 miles to Albany, where they connected with the mainline of the Oregon & California Railroad (Robertson 1995).

Logging and lumber milling were the most important industries in the early years of European American settlement of Toledo and Lincoln County. It was estimated at around 15 to 20 billion board feet of timber stood in the vicinity of Toledo, and this timber attracted capitalists intent on cashing in on this natural resource. About seventy small sawmills dotted the landscape by the close of the 19th century. During World War One, spruce lumber became a strategic war material used in the construction of airplanes, though the conflict ended before the Pacific Spruce Corporation could begin production. Pacific Spruce was renamed the C.D. Johnson Lumber Company, by 1924 the company employed 800 workers, making Toledo the industrial center of Lincoln County (City of Toledo 2021; Wikipedia 2021).

THE “TOKYO SLOUGH” RACE RIOT

On July 10, 1925, the C.D. Johnson Lumber Company hired 32 Japanese to sort lumber, or “pull chain” as the workers referred to the process. The mill managers had made the decision to hire Japanese workers months previously, and they had worked hard to cool off the simmering tensions of the European American workers who feared that the Japanese would steal jobs and undercut their wages. The decision by the mill heads even got the support of the local chamber of commerce. Despite these efforts to smooth over these concerns, just two days after the Japanese workers were hired, a mob of 50 White men, egged on by about 250 White women and children, attacked the Japanese in their homes along “Tokyo Slough.” The White mob overpowered armed mill workers who had been deputized as guards and confronted the Japanese foreman, who was beaten when he refused to leave (Corvallis Gazette-Times 7 Apr. 2005).

The police chief of Toledo did nothing to stop the White mob, and his wife was one of the most vocal and active members of the large group of White women and children who supported the rioters. The Lincoln County sheriff took down names of the White rioters and made a few arrests, but the White mob loaded the Japanese into cars and trucks and forcibly removed them to Corvallis. Five of the Japanese workers sued their attackers, and one worker won $2,500 in the first civil case, though the four other pending cases were settled by the six Whites accused in those lawsuits. Ted Cox, a Corvallis historian who published a written history of the Toledo race riot, estimated that the accused Whites paid the Japanese plaintiffs more than $7,000, or about $106,000 in 2021 dollars. As part of the settlement, the defendants also promised to not discriminate against Japanese workers (Corvallis Gazette-Times 7 Apr. 2005).

The aftermath of the race riot split the residents of Toledo, with some supporting the White rioters, and others supporting the rights of the Japanese to follow economic opportunities without outside interference. One White rioter lost his business and left the city, and another had his property auctioned off to pay his share of the settlement. The police chief and his wife paid the most and had to sell off property to meet their financial obligations. Sadly, the July 1925 race riot in Toledo was not unique, and numerous other incidents of its kind took place in Oregon and the United States throughout the 1920s (Corvallis Gazette-Times 7 Apr. 2005).

DECLINING FORTUNES

As the 20th century wore on, the economy of Toledo declined. United States Highway 20 bypassed the city and caused people and businesses to move to Newport. The depletion of timber drove the C.D. Johnson Lumber Company to the brink of failure, and the company was purchased by Georgia-Pacific in 1952. Toledo had served as the county seat of Lincoln County since 1896, and voters had failed in 1928 and 1938 to remove the county seat to Newport. The voters approved the change in 1954, and Newport became the county seat. The booming prosperity of Toledo between the 1880s and the late 1920s was driven by the timber extraction industry, but currently the Georgia-Pacific mill is the only lumber mill operating in Toledo (City of Toledo 2021; Wikipedia 2021).

THE BUILDINGS IN THE PHOTOGRAPH

The four houses and garage shown in the postcard are situated in the NE¼ of the NE¼ of the SW¼ of Section 17, Township 11 South, Range 10 West, Willamette Meridian. In April 1882, Henry S. Maynard received a patent for 166.40 acres of land in Section 17 (BLM 2021:OROCAA 032629). However, even before Maynard formally received his patent, he had sold his entire claim to Judith T. Vincent in January 1880 for $500, or about $13,000 in 2021 dollars (Lincoln County Recorder 1880). In 1890, a portion of this property was platted as Vincent’s First Addition to Toledo (Corvallis Gazette-Times 7 Mar. 1890:1). This subdivision was created prior to the formal incorporation of Toledo, which occurred either in 1893 or 1905, depending on the source consulted (City of Toledo 2021; Wikipedia 2021).

Judith T. Vincent died in October 1903, and her estate executors sold off some of her property holdings over several months after her death (Lincoln County Leader 16 Oct. 1903:1). The buildings shown on the postcard are located on Lots 1 through 7 on Block 5 of Vincent’s First Addition to Toledo. On March 3, 1904, T. H. Gildersleeve purchased Blocks 5, 6, and 9 of Vincent’s First Addition to Toledo (Lincoln County Leader 4 Mar. 1904:1). Edwin J. Avery and his wife Anna S. Avery acquired Lots 1 through 7 on Block 5 by 1911, though they lost the property to the Lincoln County Sheriff due to property tax arrears (Lincoln County Leader 3 Nov. 1916:2). G. B. McCluskey acquired the former Avery property in April 1918 (Lincoln County Leader 5 Apr. 1918:3).

The four houses and garage that appear in the postcard image all appear on the 1925 Sanborn fire insurance map (Sanborn 1925:5). The garage shown at the extreme right of the postcard image is located at the rear of the house at 814 SE Fir Street. According to tax assessor records, this house was built in 1924. The property at 741 7th Street SE was built in 1940 according to tax assessor records, but it appears that this house was constructed between 1920 and 1924 and has been extensively altered from how it appeared in 1924 when the photograph was taken. Both of the houses at 763 7th Street SE and 781 7th Street SE were built in 1920, and the house at the extreme left of the postcard image was built in 1924 (Lincoln County Assessor 2021). In summary, based on the tax assessor records, the Sanborn fire insurance map, and the postmark on the postcard, the four houses and garage along 7th Street SE were all constructed between 1920 and July 1924. A present-day image of the garage and four houses from Google Maps is shown below.

WORKS CITED

Corvallis Gazette-Times

1890 “Toledo Notes.” Corvallis Gazette-Times 7 March:1. Electronic resource, https://www.newspapers.com/, accessed April 2021.

Corvallis Gazette-Times

2005 “Local man’s book examines Toledo race riot.” Corvallis Gazette-Times, 7 April. Electronic resource, https://www.gazettetimes.com/news/local/local-mans-book-examines-toledo-race-riot/article_06a15239-ee7f-5701-97ef-20099a621f04.html, accessed April 2021.

Lincoln County Leader

1903 “Mrs. J. T. Vincent.” Lincoln County Leader 16 October:1. Electronic resource, https://www.newspapers.com/, accessed April 2021.

1904 “Real Estate Transfers.” Lincoln County Leader 4 March:1. Electronic resource, https://www.newspapers.com/, accessed April 2021.

1916 “Notice of Sheriff’s Sale.” Lincoln County Leader, 3 November:2. Electronic resource, https://www.newspapers.com/, accessed April 2021.

1918 “Announcements.” Lincoln County Leader, 5 April:3. Electronic resource, https://www.newspapers.com/, accessed April 2021.

City of Toledo

2021 “History of Toledo.” Electronic resource, https://www.cityoftoledo.org/community/page/history-toledo, accessed April 2021.

Confederated Tribes of Siletz Indians

2021 “Our Heritage.” Electronic resource, http://www.ctsi.nsn.us/chinook-indian-tribe-siletz-heritage/, accessed April 2021.

2021 Toledo, Oregon. Electronic resource, https://www.google.com/maps, accessed April 2021.

Lincoln County Assessor

2021 Property Info Search Tool. Electronic resource, https://www.co.lincoln.or.us/assessor/page/property-info-search-tool, accessed April 2021.

Lincoln County Recorder

1880 H. S. Maynard to Mrs. Judith T. Vincent, 17 June. Electronic resource, https://helion.co.lincoln.or.us/DigitalResearchRoomPublic/, accessed April 2021.

Robertson, Donald

1995 Encyclopedia of Western Railroad History, Volume 3: Oregon and Washington. The Caxton Printers, Ltd., Caldwell, Idaho.

Sanborn Map Company (Sanborn)

1925 Toledo, Lincoln County, Oregon, Sheet 2. Electronic resource, https://digitalsanbornmaps-proquest-com.ezproxy.spl.org/about?accountid=2565, accessed April 2021.

United States Department of the Interior, Bureau of Land Management (BLM)

2021 General Land Office Records. Electronic resource, https://glorecords.blm.gov/search, accessed April 2021.

2021 Land Status & Cadastral Survey Records, Willamette Meridian – Oregon and Washington States. Electronic resource, https://www.blm.gov/or/landrecords/survey, accessed April 2021.

Wikipedia

2021 “Toledo, Oregon.” Electronic resource, https://en.wikipedia.org/wiki/Toledo,_Oregon, accessed April 2021.